Running hot

#21

ok we got her tore down, noticed some pretty bad "pitting" on one of the cylinder heads, went ahead and order another one. the other one has a small indention in the same spot....anyone have any ideas???? why would it be doing this on the same spot on both of the cylinder heads? also is it better to buy new bolts? Thanks!! We decided on ordering two new cylinder heads, we noticed some thinning of the walls where what we know as the "water jacket" around the outside of the cylinders in the area where the bad pitting occured. ANYONE HAVE ANY IDEAS WHAT WOULD CAUSE THIS? It is just wear and tear are we reading too much into it or it is something bigger?? Any info is much appreciated....

Last edited by sisk; 05-28-2012 at 06:49 PM.

#22

- Pre-soak all exhaust manifold bolt with a product like PB Blaster (hit other "rusty" bolts too). It might help.

- Use Fel Pro aluminum LIM gaskets. I would also buy a Fel Pro head gasket. If you don't go Fel Pro, go with a trust worthy gasket/gasket manufacturer. Don't cheap out and get the cheap eBay stuff. It might be 100% fine, I honestly don't know, but IMO, do you want to do this job again any time soon because you cheaped out?

- Get a GOOD torque wrench. I personally would advise against a Harbor Freight torque wrench (in my limited experience, even though they claim to click, it's not very loud and you can very easily not notice it reached it's limit, plus I have heard it's not very accurate).

- I've put the push rods and rockers in baggies and labeled the bag as to there position (so I place them exactly back where they came from).

- CLEAN EVERYTHING! I used kerosene as a degreasing agent and a cheap paint brush. I also pressure washed the heads (you could do this at a car wash if you don't have a pressure wash). They were so clean when I was done, I think you could EAT off them. I also washed the rockers and the push rods (you can use an old pop bottle with a little amount of kerosene for the push rods, one at a time dip them in the bottle, swish it around).

- Make sure ALL head and LIM mating surfaces are as CLEAN as possible. If they aren't, you will regret it.

- Technically you should have the heads taken in to inspect for cracks and warps (usually a crack check is "magnaflux"). I never have. BUT, you can check easily for warping. Use straight edge and check the bottom (run that straight edge every way possible, check if anything between the head and the straight edge look out of whack).

- I wish I would have thought of this when I did the head gaskets on my '94 Grand Am, this would be an EASY time to pop on new valve seals while the heads are off (no fear of the valve dropping into the cylinder). But, I am riding on factory original valve seals at 220,000 miles, so not sure how BIG a deal that is.

- Consider a spark plug change, you have super easy access to them at this point.

- Take pictures with a digital camera of everything, label things, take your time.

- Use Fel Pro aluminum LIM gaskets. I would also buy a Fel Pro head gasket. If you don't go Fel Pro, go with a trust worthy gasket/gasket manufacturer. Don't cheap out and get the cheap eBay stuff. It might be 100% fine, I honestly don't know, but IMO, do you want to do this job again any time soon because you cheaped out?

- Get a GOOD torque wrench. I personally would advise against a Harbor Freight torque wrench (in my limited experience, even though they claim to click, it's not very loud and you can very easily not notice it reached it's limit, plus I have heard it's not very accurate).

- I've put the push rods and rockers in baggies and labeled the bag as to there position (so I place them exactly back where they came from).

- CLEAN EVERYTHING! I used kerosene as a degreasing agent and a cheap paint brush. I also pressure washed the heads (you could do this at a car wash if you don't have a pressure wash). They were so clean when I was done, I think you could EAT off them. I also washed the rockers and the push rods (you can use an old pop bottle with a little amount of kerosene for the push rods, one at a time dip them in the bottle, swish it around).

- Make sure ALL head and LIM mating surfaces are as CLEAN as possible. If they aren't, you will regret it.

- Technically you should have the heads taken in to inspect for cracks and warps (usually a crack check is "magnaflux"). I never have. BUT, you can check easily for warping. Use straight edge and check the bottom (run that straight edge every way possible, check if anything between the head and the straight edge look out of whack).

- I wish I would have thought of this when I did the head gaskets on my '94 Grand Am, this would be an EASY time to pop on new valve seals while the heads are off (no fear of the valve dropping into the cylinder). But, I am riding on factory original valve seals at 220,000 miles, so not sure how BIG a deal that is.

- Consider a spark plug change, you have super easy access to them at this point.

- Take pictures with a digital camera of everything, label things, take your time.

#24

Join Date: Apr 2010

Location: Mentor, Ohio

Posts: 12,175

Can you upload any pics of what you are looking at? Those would help a little. Below is a pic from the 3100 in my Grand Am when I did the head gaskets on it (I stayed with the same heads, just did the "poor man's check for flatness", otherwise, I'd send them to a machine shop to be checked and magnafluxed for cracks).

As for buying new bolts, I have re-used existing head bolts. As I understand, everytime you torque a bolt it "stretches", hence why it's recommended to "replace" with new bolts. If the bolts are in good condition and this is the first time they've been re-used, odds are, no problems for a street car (if this car is going to be used purely for racing, I'd replace them). Just for example, I did my head gaskets in October 2009 with 180K on the clock. I am STILL driving that Grand Am with now approaching 220K!!

As for pitting, make sure it's not old gasket material holding onto the heads. I scraped some gasket material with a razor blade. Then I followed up with something like this on my power drill:

2"& 3" Fiber Disc Sanding Kit

It's like a red scotchbrite pad. Does a great job. Before doing this, cover where the intake sits (try to help avoid crap falling in). Don't go nuts, as you don't want it to work any metal off the decking/mating surfaces (that could damage "flatness", but you have to be really working a spot for a long time aggressively to do that). Those fibers I hear can be harmful if left in the engine. I advise using an air compressor to blow the area clean once you are done. I also cleaned the heck out of my heads. Once I had the heads on, before putting the intake on, this might have been over the top BUT, I splashed a little kerosene (it acts as a degreaser) down where the intake sits (trying to "catch" any crap and drag it to the crank case). Then a quart of oil to follow a couple minutes later.

Remember, you DO NOT start that engine until you have changed oil and filter!!! Odds are a lot of coolant and crap has gone into the crank case and right before starting that engine is a GREAT time to empty it. Also, drive the car about 500 miles when you are done, change the oil again (one oil change is not enough to "flush" all the crap out).

I hope that info is of help.

As for buying new bolts, I have re-used existing head bolts. As I understand, everytime you torque a bolt it "stretches", hence why it's recommended to "replace" with new bolts. If the bolts are in good condition and this is the first time they've been re-used, odds are, no problems for a street car (if this car is going to be used purely for racing, I'd replace them). Just for example, I did my head gaskets in October 2009 with 180K on the clock. I am STILL driving that Grand Am with now approaching 220K!!

As for pitting, make sure it's not old gasket material holding onto the heads. I scraped some gasket material with a razor blade. Then I followed up with something like this on my power drill:

2"& 3" Fiber Disc Sanding Kit

It's like a red scotchbrite pad. Does a great job. Before doing this, cover where the intake sits (try to help avoid crap falling in). Don't go nuts, as you don't want it to work any metal off the decking/mating surfaces (that could damage "flatness", but you have to be really working a spot for a long time aggressively to do that). Those fibers I hear can be harmful if left in the engine. I advise using an air compressor to blow the area clean once you are done. I also cleaned the heck out of my heads. Once I had the heads on, before putting the intake on, this might have been over the top BUT, I splashed a little kerosene (it acts as a degreaser) down where the intake sits (trying to "catch" any crap and drag it to the crank case). Then a quart of oil to follow a couple minutes later.

Remember, you DO NOT start that engine until you have changed oil and filter!!! Odds are a lot of coolant and crap has gone into the crank case and right before starting that engine is a GREAT time to empty it. Also, drive the car about 500 miles when you are done, change the oil again (one oil change is not enough to "flush" all the crap out).

I hope that info is of help.

#26

OMG they sold us the wrong freaking heads!!!! Went to start putting it back on today and they sold us the 10 mm heads instead of the 8. Weren't even aware there were two different ones. They never mentioned it when we ordered them. Anyway, they are getting the correct ones but when I was torching them the haynes stated 44 lbs and 95 degrees. When I was taking them back off the back ones seemed nowhere near as tight as the front on the back one. Did you have any problems with the torch? Thanks again for all your information.

#27

Join Date: Apr 2010

Location: Mentor, Ohio

Posts: 12,175

I had no issues with torque on my heads. When removing, they were both equally as tight.

FYI - The Haynes book may not be 100% correct in torque spec. What year is your 3400? I can check against a shop book for you.

I had to torque my heads to such-a-such foot lbs + 90 degrees. Those things are TIGHT when done.

FYI - The Haynes book may not be 100% correct in torque spec. What year is your 3400? I can check against a shop book for you.

I had to torque my heads to such-a-such foot lbs + 90 degrees. Those things are TIGHT when done.

#28

2005, I found a website Summit Racing that has 65 lbs for a small chevy engine. I was going to go with that on the new set of heads, but yes if you have access, it would be very much appreciated. I am old school and back when I worked on my hotrods under a shade tree they were set at about 96 lbs even no degrees.

#29

Join Date: Apr 2010

Location: Mentor, Ohio

Posts: 12,175

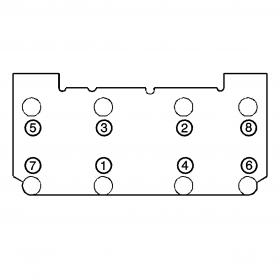

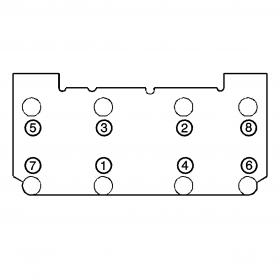

Per the shop book:

- Tighten the cylinder head bolts a first pass in sequence to 60 N·m (44 lb ft).

- Tighten the cylinder head bolts a final pass in sequence to 95 degrees using the J 45059 .