?> World's Most Advanced Gas Engine? <?

#1

World's Most Advanced Gas Engine? We Interview Chief Technology Officer at Duke Engines

Member's, post your thoughts on this new designed engine ? without valves & lighter ? I'm impressed...., are you ?

By Justin Mendenhall 18 hours ago

By Justin Mendenhall 18 hours ago

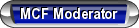

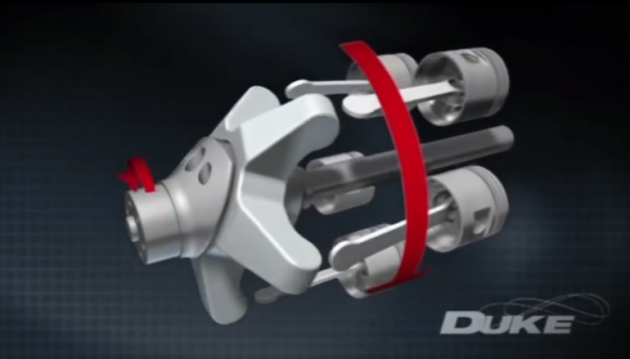

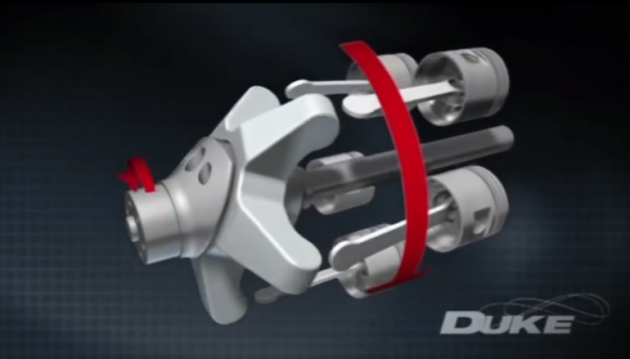

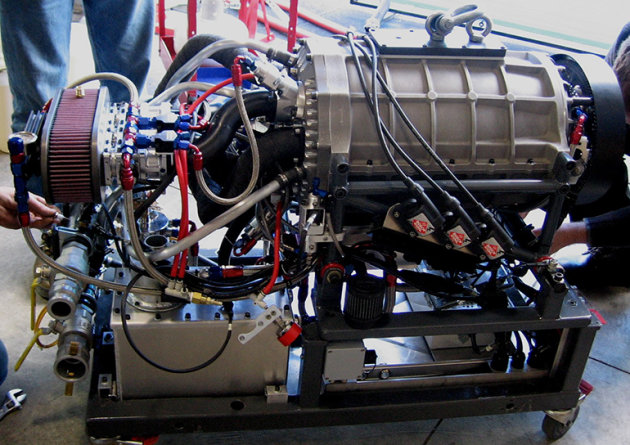

Yesterday we posted a story on the Duke Engines 5-cylinder Axial engine, a 1,000cc beast tiny in size, which features little to no vibration, no valves, fewer moving parts and makes 125 hp. We hope to see it in a motorcycle soon, but in the mean time we spoke with the Chief Technology Officer at Duke Engines, Dr. Mike Fry, to find out how practical the engine really is, what its limitations are, and the future of Duke Engines.

READ THE ORIGINAL STORY HERE: The Most Advanced Gas-Burning Engine Ever in a Motorcycle Concept - The Duke Axial Engine

What can you see in the future for axial motors with regards to building a Duke powered prototype motorcycle?

We would like to do it; it is a suitable application and would make good use of Duke DNA – high power density small size and weight. It is hard to justify a development program on the volumes of 1 motorcycle application; it would most likely be achieved as a spin-off from a light aircraft, marine or some other program.

Your design is drastically different- allowing this gyroscopic effect to be reduced or maybe disappear?

That is correct – the counter rotating cylinder group and crankshaft tend to cancel out gyroscopic reactions. It is possible to completely cancel these reactions, but in practice it may not be needed to go that far, preferring to optimize solution for a balance of weight, gyro effects, size, performance etc. The counter rotating parts also accelerate/decelerate in opposing directions during a firing torque-pulse, reducing the associated torque reaction of the engine on its mounts.

Can your design allow this to change drastically?

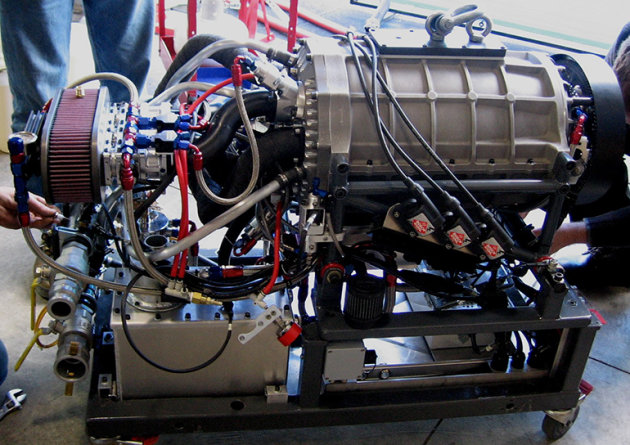

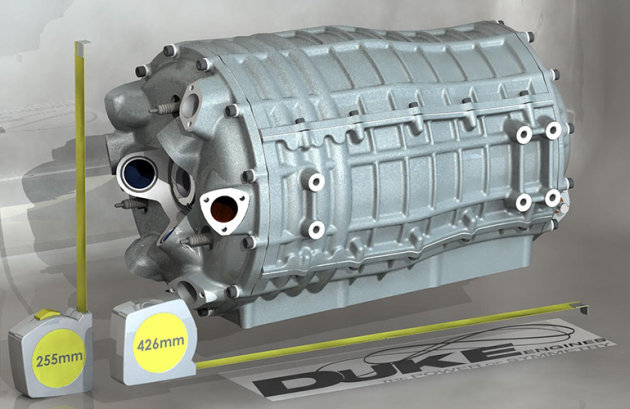

The Duke design offers a radically different package shape to conventional engines – a compact cylinder with the output shaft on the central axis, more akin to the shape of an electric motor. This offers a new set of possibilities for design and integration of the engine into a motorcycle chassis – or car/generator or aircraft, for that matter.

Can a 1000cc axial motor be built without expensive exotic materials, ie. Titanium?

Yes – we currently use titanium connecting rods in our prototype engines, but the use of exotic materials is optional, depending upon the cost/performance trade off sought – just as with a conventional engine.

Can your design allow for an exchangeable gearbox for ratio change?

Yes – a conventional gearbox and drive system would be used with a Duke engine.

In regards to power delivery and traction, cross plane crankshafts are known to give the rider more feeling from the rear tire. Promoting confidence and grip while accelerating is a big factor when dealing with 160+ HP. To avoid a high-side crash this type of mechanical feature helps the rider from getting his rear wheel spinning faster than his motor (by feeling the tire and his available traction). The 5 cylinder Duke engine fires 3 times/rev of the output shaft – the same as a 6 cylinder conventional engine. The power delivery would be expected to be equally smooth and would allow for better feel/less tendency to break tire traction than the “lumpy” impulsive torque delivery associated with 4 cylinders or less. The 3 fire events/rev also increases torque by 20% compared to conventional engines with the same displacement – Duke 3.0 naturally aspirated prototypes have produced 113 Nm/l, for example.

READ MORE: How To Break In a New Motorcycle Engine

What RPM have you reached with little or no vibration?

We have run our 3.0L prototypes up to 4500 rpm crankshaft speed, full load (215 hp and 340Nm), with a full design speed of 6000 rpm; the pistons are moving 20% faster than conventional engines, due to the counter rotating cylinders/crankshaft. Smaller displacement motorcycle engines would be expected to rev much higher. We have not completed vibration testing, but the complete primary balance and negligible secondary vibration offers fundamentally better prospects than 2, 3 or 4 cylinder inline engines. See the “coin trick” of a $2 coin standing on edge while the engine is started, revved, and stopped.

What do you think the minimum weight would be for the 1000cc motor in a motorcycle? Taking into account 1 motor using conventional materials and 1 using titanium, magnesium etc.

The numbers sent in the 1000cc concept are best estimate for a road bike derivative using conventional materials. Up to a further 30% might be saved with aggressive use of Titanium for internal components/exhaust and carbon fiber for external housings and intake system – in an “all-out” race application. The external casing is lightly loaded (internal rotating structure carries the majority of gas and reciprocating inertial loads) so it can be made very light – think “outer shell” not “cylinder block”.

Can the Axial motor be built to have a final drive shaft that allows for chain/drive sprocket on either side of the motor, like in a transverse mounted engine?

The output drive shaft can be taken from either end. We conventionally take drive out through the opposite end to the manifolding to allow maximum package space for the intake ports/pipes etc.

READ MORE: 5 Forced Induction Sportbikes That Made History | RideApart

What is the firing order currently on your newest prototype engine?

A curiosity of the Duke engine is that the 5 cylinders share the 3 injectors and spark plugs as they slide past each in turn. The result is a “firing order” for our 5 -cylinder engine of 1, 2, 3 – rotates around the 3 sparkplugs in turn.

What is possible in the future, in a motorcycle engine?

Lighter weight, smaller size and a new set of chassis design freedoms. The center of gravity of the Duke engine lies on the crankshaft axis (like a boxer engine or Wankel) – much lower than in a typical “stand-up” inline layout.

Photos courtesy of Duke Engines

Member's, post your thoughts on this new designed engine ? without valves & lighter ? I'm impressed...., are you ?

By Justin Mendenhall 18 hours ago

By Justin Mendenhall 18 hours ago Yesterday we posted a story on the Duke Engines 5-cylinder Axial engine, a 1,000cc beast tiny in size, which features little to no vibration, no valves, fewer moving parts and makes 125 hp. We hope to see it in a motorcycle soon, but in the mean time we spoke with the Chief Technology Officer at Duke Engines, Dr. Mike Fry, to find out how practical the engine really is, what its limitations are, and the future of Duke Engines.

READ THE ORIGINAL STORY HERE: The Most Advanced Gas-Burning Engine Ever in a Motorcycle Concept - The Duke Axial Engine

What can you see in the future for axial motors with regards to building a Duke powered prototype motorcycle?

We would like to do it; it is a suitable application and would make good use of Duke DNA – high power density small size and weight. It is hard to justify a development program on the volumes of 1 motorcycle application; it would most likely be achieved as a spin-off from a light aircraft, marine or some other program.

Your design is drastically different- allowing this gyroscopic effect to be reduced or maybe disappear?

That is correct – the counter rotating cylinder group and crankshaft tend to cancel out gyroscopic reactions. It is possible to completely cancel these reactions, but in practice it may not be needed to go that far, preferring to optimize solution for a balance of weight, gyro effects, size, performance etc. The counter rotating parts also accelerate/decelerate in opposing directions during a firing torque-pulse, reducing the associated torque reaction of the engine on its mounts.

Can your design allow this to change drastically?

The Duke design offers a radically different package shape to conventional engines – a compact cylinder with the output shaft on the central axis, more akin to the shape of an electric motor. This offers a new set of possibilities for design and integration of the engine into a motorcycle chassis – or car/generator or aircraft, for that matter.

Yes – we currently use titanium connecting rods in our prototype engines, but the use of exotic materials is optional, depending upon the cost/performance trade off sought – just as with a conventional engine.

Can your design allow for an exchangeable gearbox for ratio change?

Yes – a conventional gearbox and drive system would be used with a Duke engine.

In regards to power delivery and traction, cross plane crankshafts are known to give the rider more feeling from the rear tire. Promoting confidence and grip while accelerating is a big factor when dealing with 160+ HP. To avoid a high-side crash this type of mechanical feature helps the rider from getting his rear wheel spinning faster than his motor (by feeling the tire and his available traction). The 5 cylinder Duke engine fires 3 times/rev of the output shaft – the same as a 6 cylinder conventional engine. The power delivery would be expected to be equally smooth and would allow for better feel/less tendency to break tire traction than the “lumpy” impulsive torque delivery associated with 4 cylinders or less. The 3 fire events/rev also increases torque by 20% compared to conventional engines with the same displacement – Duke 3.0 naturally aspirated prototypes have produced 113 Nm/l, for example.

READ MORE: How To Break In a New Motorcycle Engine

What RPM have you reached with little or no vibration?

We have run our 3.0L prototypes up to 4500 rpm crankshaft speed, full load (215 hp and 340Nm), with a full design speed of 6000 rpm; the pistons are moving 20% faster than conventional engines, due to the counter rotating cylinders/crankshaft. Smaller displacement motorcycle engines would be expected to rev much higher. We have not completed vibration testing, but the complete primary balance and negligible secondary vibration offers fundamentally better prospects than 2, 3 or 4 cylinder inline engines. See the “coin trick” of a $2 coin standing on edge while the engine is started, revved, and stopped.

What do you think the minimum weight would be for the 1000cc motor in a motorcycle? Taking into account 1 motor using conventional materials and 1 using titanium, magnesium etc.

The numbers sent in the 1000cc concept are best estimate for a road bike derivative using conventional materials. Up to a further 30% might be saved with aggressive use of Titanium for internal components/exhaust and carbon fiber for external housings and intake system – in an “all-out” race application. The external casing is lightly loaded (internal rotating structure carries the majority of gas and reciprocating inertial loads) so it can be made very light – think “outer shell” not “cylinder block”.

Can the Axial motor be built to have a final drive shaft that allows for chain/drive sprocket on either side of the motor, like in a transverse mounted engine?

The output drive shaft can be taken from either end. We conventionally take drive out through the opposite end to the manifolding to allow maximum package space for the intake ports/pipes etc.

READ MORE: 5 Forced Induction Sportbikes That Made History | RideApart

What is the firing order currently on your newest prototype engine?

A curiosity of the Duke engine is that the 5 cylinders share the 3 injectors and spark plugs as they slide past each in turn. The result is a “firing order” for our 5 -cylinder engine of 1, 2, 3 – rotates around the 3 sparkplugs in turn.

What is possible in the future, in a motorcycle engine?

Lighter weight, smaller size and a new set of chassis design freedoms. The center of gravity of the Duke engine lies on the crankshaft axis (like a boxer engine or Wankel) – much lower than in a typical “stand-up” inline layout.

Photos courtesy of Duke Engines

Last edited by Space; 12-19-2014 at 06:08 AM.

#2

By Justin Mendenhall - December 17, 2014

Categories: Technology, Expert Advice, Racing, Design

Over the last few decades there have been some astounding technological advances in the world of motorcycles. Wiz Bang electronics that rival fighter jet avionics, space age chassis construction, Italian built brakes that can stop a freight train and engine components constructed of rare elements - these are normal attributes for motorcycles on the showroom floor. In this day and age has the development of new technologies reached their crescendo? If you ask someone at the New Zealand based Duke Engines, you'd get a firm no. Duke may have the next evolutionary step in gas-burning engines that may see its way to motorcycles: the axial.

READ MORE: Tips on Becoming a Better Motorcycle Rider | RideApart

The Duke axial engine is arguably one of the most advanced gas-burning engines ever made, but has it come it too late? As we're constantly reporting on advances in electric power, is the gas engine done for good regardless of the engineering power?

What is it?

For 17 years Duke’s opus has been the axial engine. “Situated around, in the direction of, on, or along an axis,” that's the definition of axial, so you may be able to guess how this valveless, compact engine works.

READ MORE: How To Break In A New Motorcycle Engine | RideApart

From the outside, Dukes' prototype appears to be un-cluttered and nothing like a conventional internal combustion engine. Currently the company is working on motors that fit within the aerospace, marine and automotive applications.

Motorcycles

The technology Duke is quietly perfecting is not just another hornswoggle; it looks to be both real and progressive. Interesting is the axial design and what it could offer the two-wheeled world as a lighter, smaller, smoother and equally powerful alternative to the contemporary engine.

There have been in the past some notable attempts to deliver unique engine options that have won championships and delivered quality to the market- some with great success. There are many configurations - V4, V twin, inline 3’s and 4’s, parallel twins, flat 4’s and Honda’s V5 GP engine to name a few. All of these variants featured camshafts and valves, while the Axial has neither. Some are probably even made with adamantium stolen from Wolverine, (well maybe not) - but who really knows what's actually in Honda’s GP RC211V engine?

The venerable Wankel engine is a stark contrast to high performance motors of today and it also possesses no such things as cams, valves (or adamantium). As a rotary engine it was designed with less parts but in the end couldn't deliver the performance with the required reliability.

In 1974 Suzuki produced its heavy Wankel RE5 but ended the model in 1976 and Norton won at the Isle of Man with their rotary powered NRS 588 piloted by Steve Hislop, winning the 1992 senior TT. Duke’s revolver arranged, 5-cylinder axial engine - although yet untested in a motorcycle - possesses several more qualities and improvements in comparison to the older rotary motor design.

One very important aspect is that it has gone through an exceptionally long development and there’s empirical data to prove performance. It could possibly take motorcycle design a step further - smaller physical size, smaller/lighter engine weight, less vibration, less moving parts, sans cam shafts and valves and a longitudinal crank that requires no counter balance shafts. The “so what?” is maybe found in the forces of physics that surround motorbikes, and how the Duke engine could counter them.

It's Not Science It's Magic

An expert once said - “The ability to destroy a planet is insignificant next to the power of the force.” One of these forces is what everyone knows as gyroscopic effect and its ability to magically interact with gravity. Not related to force choking or light saber skills however, these forces of real physics are just as cool.

Without having to open the textbook anyone who watches Marq Marquez drag his elbow at 60% lean angle knows that the force is a wondrous thing. Sport bikes by design are to operate at the very edge of physics and are ridden by racers that are good enough to do so. Add two spinning wheels, crankshaft, pistons, connecting rods, fly wheel, drive chain, cam belts, sprockets etc. all moving in directions that can counter the riders steering inputs and the rotation of the wheels.

With a transverse crank and output shaft (perpendicular to the direction of the bikes travel) it requires force to move the bike laterally due to the two gyros (wheels) and an engine that’s running at a high RPM. With the symmetrical Axial motor there’s little to no vibration with the engine spinning in a neutral direction, also not fighting as much with the gyroscopic effect of the spinning tires. This is a very interesting proposition. Of course, there are shaft driven motors, chassis and other options available to everyone right now that can help with bike stability.

Duke’s 1000cc motor is advertising a 1.14 to 1 power (hp) to weight (lbs.) ratio in a package that fits in a carry-on bag.

Time (and more importantly money) will tell if Duke's axial engines will literally get off the ground. According to the company there is the possibility in the short future that UAV’s and small aircraft will be using the axial engine for their power plants. A bigger hope for motorcycle fans is that one day they will see a Duke powered motorbike jumping Ballaugh Bridge at the Isle of Man or a bike available for purchase at the local dealer.

5 Cylinder, 1000cc, 125HP

Here are the specifics on the 5 cylinder, 1000cc prototype: 67 x 56 Bore and Stroke (mm), 125 HP @ 7,500 RPM (max engine output speed) with 119 NM of torque. The engine weight is 86 pounds including ancillary parts- minus the starter-generator. The bare engine dimensions are diminutive-16.69 L x 9.52 W x 9.52 H (inches).

READ MORE: The Future of Motorcycling, We Ride the Honda NM4 - RideApart

Photos courtesy of Duke Engines

Thread

Thread Starter

Forum

Replies

Last Post

Space

Off Topic

7

03-15-2012 11:20 AM

Scooby doo

General Monte Carlo Talk

15

12-29-2009 05:02 PM

Cowboy6622

Off Topic

4

07-10-2008 05:41 AM