Custom Fuse Box for Engine Bay

#1

Instead of totally getting my previous post off topic, I assumed that it would be easier to just create a new thread dedicated to the topic above.

Since the previous thread confirmed that I can have my battery relocated with no issues (I hope lol) I now will need something to fill the void where the battery used to be.

Ever since I started paying more attention under the hood and trying to clean things up, I've hated the placement of the fuse box. And the fact that there's no cover over it kind of annoys me. There are a few great posts here about making various covers but since I didn't want to just copy what someone else has done, I decided to think outside of the box a little.

Plan is to make a custom box that can house the fuses. I do like the way in which they are held by the OEM mount, so I'm not totally hacking the old one up. I actually managed to save a majority of it. Going to mount it in a location similar to where the batter was. An aluminum case with a plexiglass lid over the fuses so that they can still be seen. I'm considering some LEDs within the lid to light them up, should be cool right?

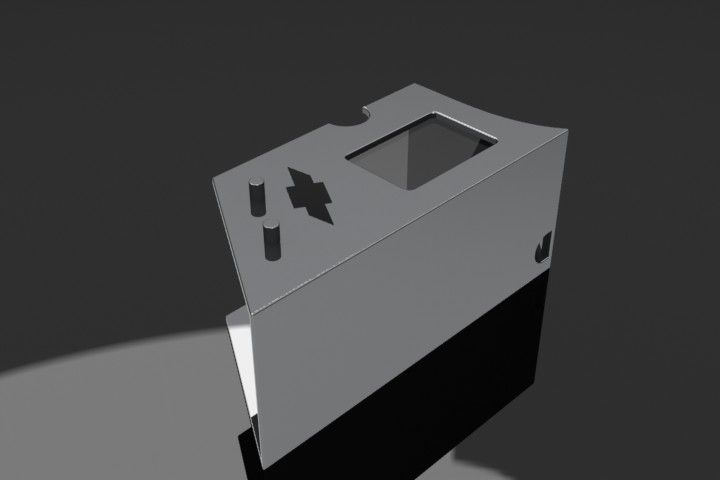

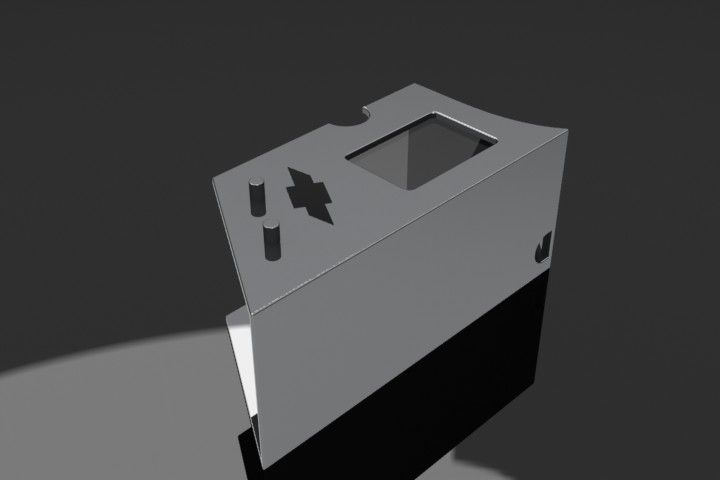

Here's my rendering of the box. Not to exact specs, but I figured I'd mock something up and see if it's do-able and can look good before I start tearing in and end up with a costly project.

Here's what I have so far with the OEM fuse box housing. Going to keep this as close to stock as possible so that the fuses can easily clip back into this housing. Should help keep it clean. Going to replace the screws with bolts tonight once I make a trip to Lowes.

Also, I'm not modifying the wires or harnesses in any way. Going to work with what I have and if I can tuck some wires in the process, it will be done without any cutting or splicing. (Kinda scares me to cut into any wires under the hood aside from when I put in new injectors)

aside from when I put in new injectors)

Thanks for looking, I'm hoping to have this project done by the 22nd (car show that day), so stop back for updates if you can

Since the previous thread confirmed that I can have my battery relocated with no issues (I hope lol) I now will need something to fill the void where the battery used to be.

Ever since I started paying more attention under the hood and trying to clean things up, I've hated the placement of the fuse box. And the fact that there's no cover over it kind of annoys me. There are a few great posts here about making various covers but since I didn't want to just copy what someone else has done, I decided to think outside of the box a little.

Plan is to make a custom box that can house the fuses. I do like the way in which they are held by the OEM mount, so I'm not totally hacking the old one up. I actually managed to save a majority of it. Going to mount it in a location similar to where the batter was. An aluminum case with a plexiglass lid over the fuses so that they can still be seen. I'm considering some LEDs within the lid to light them up, should be cool right?

Here's my rendering of the box. Not to exact specs, but I figured I'd mock something up and see if it's do-able and can look good before I start tearing in and end up with a costly project.

Here's what I have so far with the OEM fuse box housing. Going to keep this as close to stock as possible so that the fuses can easily clip back into this housing. Should help keep it clean. Going to replace the screws with bolts tonight once I make a trip to Lowes.

Also, I'm not modifying the wires or harnesses in any way. Going to work with what I have and if I can tuck some wires in the process, it will be done without any cutting or splicing. (Kinda scares me to cut into any wires under the hood

aside from when I put in new injectors)

aside from when I put in new injectors)

Thanks for looking, I'm hoping to have this project done by the 22nd (car show that day), so stop back for updates if you can

Last edited by 01 Monte SS; 09-12-2012 at 02:32 PM.

#2

Cool idea  Solidworks rocks!

Solidworks rocks!

Is the car show you are talking about the one in Webster City?

Are you going to fab the box? How are you going to cut and form the aluminum?

Solidworks rocks!

Solidworks rocks!Is the car show you are talking about the one in Webster City?

Are you going to fab the box? How are you going to cut and form the aluminum?

Last edited by zzapultimate; 09-12-2012 at 02:49 PM.

#3

I have no idea how I'm going to get the box made yet

Still debating on how I can get it done. May just cut out the exterior pieces and have them welded together, or bolt it together and just put some type of edge trim on so the edges aren't so sharp. It won't look as clean as my solidworks assembly

Still debating on how I can get it done. May just cut out the exterior pieces and have them welded together, or bolt it together and just put some type of edge trim on so the edges aren't so sharp. It won't look as clean as my solidworks assembly  More than likely I'll also have to make the top piece on some sort of hinge so I can just open it up to change any fuses.

More than likely I'll also have to make the top piece on some sort of hinge so I can just open it up to change any fuses.

#4

Yeah are you going to the show? You should

I have no idea how I'm going to get the box made yet Still debating on how I can get it done. May just cut out the exterior pieces and have them welded together, or bolt it together and just put some type of edge trim on so the edges aren't so sharp. It won't look as clean as my solidworks assembly

Still debating on how I can get it done. May just cut out the exterior pieces and have them welded together, or bolt it together and just put some type of edge trim on so the edges aren't so sharp. It won't look as clean as my solidworks assembly  More than likely I'll also have to make the top piece on some sort of hinge so I can just open it up to change any fuses.

More than likely I'll also have to make the top piece on some sort of hinge so I can just open it up to change any fuses.

I have no idea how I'm going to get the box made yet

Still debating on how I can get it done. May just cut out the exterior pieces and have them welded together, or bolt it together and just put some type of edge trim on so the edges aren't so sharp. It won't look as clean as my solidworks assembly

Still debating on how I can get it done. May just cut out the exterior pieces and have them welded together, or bolt it together and just put some type of edge trim on so the edges aren't so sharp. It won't look as clean as my solidworks assembly  More than likely I'll also have to make the top piece on some sort of hinge so I can just open it up to change any fuses.

More than likely I'll also have to make the top piece on some sort of hinge so I can just open it up to change any fuses.

Forming it might be cheaper/easier than welding. If you can figure out the flat pattern for the bottom plus the side and then you could bend the side up. If it's thin aluminum you should be able to bend it yourself with a makeshift brake. Then you can cut out the top of it and fab up some sort of hinge with tiny nuts and bolts. You'll be able to make the whole thing yourself this way

Just some ideas!

Just some ideas!

Last edited by zzapultimate; 09-12-2012 at 02:58 PM.

#5

I'm thinking about it

Forming it might be cheaper/easier than welding. If you can figure out the flat pattern for the bottom plus the side and then you could bend the side up. If it's thin aluminum you should be able to bend it yourself with a makeshift brake. Then you can cut out the top of it and fab up some sort of hinge with tiny nuts and bolts. You'll be able to make the whole thing yourself this way Just some ideas!

Just some ideas!

Forming it might be cheaper/easier than welding. If you can figure out the flat pattern for the bottom plus the side and then you could bend the side up. If it's thin aluminum you should be able to bend it yourself with a makeshift brake. Then you can cut out the top of it and fab up some sort of hinge with tiny nuts and bolts. You'll be able to make the whole thing yourself this way

Just some ideas!

Just some ideas!

#6

This looks super tempting. Not too bad in price assuming it will yield clean bends

18" Mini Sheet Metal Bender Fabrication Bending Forming Brake | eBay

18" Mini Sheet Metal Bender Fabrication Bending Forming Brake | eBay

#7

This looks super tempting. Not too bad in price assuming it will yield clean bends

18" Mini Sheet Metal Bender Fabrication Bending Forming Brake | eBay

18" Mini Sheet Metal Bender Fabrication Bending Forming Brake | eBay

That says 18 gauge max.. what were you thinking for thickness? I think 18 would be about right, no?

That says 18 gauge max.. what were you thinking for thickness? I think 18 would be about right, no?You probably can't get it fabricated somewhere else cheaper than $50.. plus you'll have it to use in the future. Try searching homemade brakes too.. I've seen some pretty simple ones built for cheap.

#8

That's exactly what I was thinking  That says 18 gauge max.. what were you thinking for thickness? I think 18 would be about right, no?

That says 18 gauge max.. what were you thinking for thickness? I think 18 would be about right, no?

You probably can't get it fabricated somewhere else cheaper than $50.. plus you'll have it to use in the future. Try searching homemade brakes too.. I've seen some pretty simple ones built for cheap.

That says 18 gauge max.. what were you thinking for thickness? I think 18 would be about right, no?

That says 18 gauge max.. what were you thinking for thickness? I think 18 would be about right, no?You probably can't get it fabricated somewhere else cheaper than $50.. plus you'll have it to use in the future. Try searching homemade brakes too.. I've seen some pretty simple ones built for cheap.

Custom fabrication of a box could easily be more expensive than some aluminum and that brake I bet

#9

Just bought the 18 inch sheet metal bender. Now to go to Lowes and get some supplies

Should also come in handy for my intake box. If you ever need a sheet metal brake, you know where to find one in Ames lol.

Should also come in handy for my intake box. If you ever need a sheet metal brake, you know where to find one in Ames lol.

#10

Great! I can see that tool being useful in the future. Looking forward to the results!